Share this

The Importance of Compliance Management in PLM integration

by Meghan Dey on Mar 25, 2022 3:53:03 PM

It is possible to derive value from Product Lifecycle Management (PLM) solutions in a variety of ways, including: faster introduction of products; lower cost of products; increased product sales; higher product quality; reduced waste; and more valuable product portfolios. However, compliance management is one area that does not receive nearly as much attention as it should. The difficulty with failing to manage compliance is that a substantial portion of the value associated with Product Lifecycle Management is dependent on handling compliance in a cost-effective manner. On the other hand, substantial non-compliance incidents that have a negative impact on the business through fines and penalties, unfavorable publicity, or the inability to sell new products in important markets, which may swiftly undo all of the benefits gained through PLM. Although compliance risk is not a widely discussed topic, it is vital to the creation and selling of successful products, as well as to the achievement of responsible, long-term business profitability.

Keep on reading to understand the importance of compliance management in PLM integration and how it is critical to acceleration of product development.

How is compliance critical to product value?

Product lifecycle management requires organizations to guarantee that they are adhering to both regulatory standards and internal company guidelines throughout the process. In fact, we may assume that PLM's value proposition is even jeopardized in the absence of a compliance plan as compliance management is one of the major factors in speeding up the time it takes to bring the products to the market. As a result of improved product management driven by compliance management, businesses are able to shorten product development cycles, improve supply chain efficiency, and effectively commercialize their goods in order to thrive.

Additionally, a PLM system aims to reduce the cost of a product or design. Companies have been able to dramatically lower the cost of their goods by aggressively controlling both internal and supply chain expenses throughout the product design process. Increased margins or competitive pricing can be achieved as a result of this lower cost if the savings are passed on to the consumers. Complying with rules and regulations is essential to reaping the advantages. After a product is launched to the market, it may need to be redesigned to conform with regulatory standards if it was designed in violation of those rules.

When it comes to ensuring compliance, the design may need the use of extra pollution control equipment during manufacture, safe packaging, rigorous storage conditions, and particular waste disposal. Designers have a much less window of opportunity to make adjustments once a product is published and in use by customers. To keep product prices down, the sooner compliance concerns are dealt with, the more alternatives the designer has. As time passes, there are less alternatives, and as a result, the price rises. These expenses aren't restricted to the price of ingredients or parts. Another area where least cost designs might lose their advantage fast is increased handling, shipping, manufacturing and regulatory fines.

What are the consequences of non-compliance in product development?

Most of the demonstrated value that can be achieved by a good PLM program is at risk because of non-compliance. The comparison of value to possible downfall assists to underline the necessity of regulatory compliance within a PLM strategy, even if the benefits and potential hazards are not always clearly associated. Product lifecycle management (PLM) may help companies get their product development house in order, but without a solid foundation that reduces the risk of non-compliance, it’s value may serve no real purpose.

Given below are some of the critical product development factors and phases that are dependent on compliance.

- Time to market is especially dependent on compliance.

- Delays in product design: Redesigning or reformulating the product to handle compliance can take a significant amount of time if it isn't included from the start.

- Understanding new regulations: Regulators and jurisdictions can have a substantial impact on how a product is regulated depending on where it is sold.

- Workflow interruptions: The use of limited materials may need extensive design redesign if a product is developed without an understanding of its intended market.

A lack of early detection of the above factors can have a major impact on the time it takes to bring a product to market.

|

PLM Value |

Drawbacks of Non-compliance |

|

Accelerated time to market |

Delays in product commercialization |

|

Reduction in product cost |

Last moment design changes |

|

Decreased development cost |

Design rework |

|

Boosted Value of Product Portfolio |

Product and company value discounted for risk |

|

Enhanced innovation |

Belated design constraints |

|

Improved Handover from R&D to Manufacturing |

Last moment labeling and repacking issues |

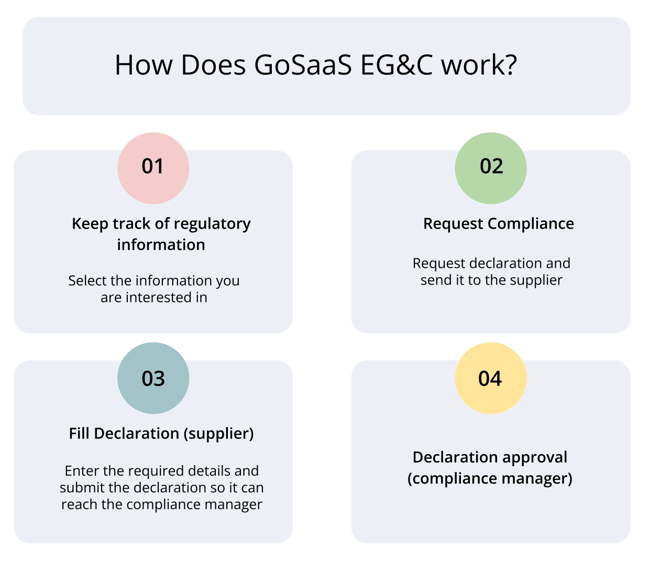

How does compliance management work?

When it comes to compliance management, modern product lifecycle management (PLM) software is rising to the occasion to assist companies in managing their day-to-day compliance obligations to rapidly changing standards and regulations, as well as making smarter long-term purchasing decisions.

PLM may also give a complete view of supplier activities by providing a "single version of the truth" regarding items. Tracking and monitoring may be used for practically all aspects of compliance, including written, oral, photographic, and even GPS-location-stamped data for authenticity. By having a better understanding of compliance performance, companies can quickly adjust to changing demands, eliminate supply interruptions and manage risk.

What are the top business processes which may be improved by compliance management?

What are the top business processes which may be improved by compliance management?

Companies need to assure regulatory compliance at every stage of product creation; from assessing chemicals and their potency within the product, through testing, storage, labeling, packaging, and product claims. It takes a lot of effort and money, however, it is very necessary as mistakes in compliance may have a significant financial and reputation impact on the product value.

Given below are some of the challenges that businesses face, which may be improved by compliance management.

Staying organized and up-to-date

A Product Information File (PIF) for each product must be kept up-to-date with the most recent regulatory documents. During an audit, if this paperwork is out-of-date or absent, major difficulties are likely to arise.

Compliance creates a massive amount of data, which is typically dispersed across many departments or even vendors. Businesses need to combine this data in one place to ensure continuity, save time, avoid mistakes and job duplication, and ultimately to remain compliant with regulations.

Being aware of international regulations

Compliance regulations vary across countries and across different economic areas. It's exceedingly important for industries, for e.g cosmetics and personal care companies, to be able to link product information directly to regulatory ingredient databases for each region so that they can make sure that the right rules are being followed.

Companies that are able to manage and streamline compliance data and processes to make sure that they stay the same across the country and around the world not only cut down on costly risks, but they also stand to stay ahead of the competition when they move into new markets across the country and around the world.

Verifying product claims

Errors in labeling or product claims can lead to unfortunate and costly lawsuits from rivals or regulators, which can lead to product recalls and the costs of re-packaging and re-marketing. Erroneous claims may be rare, but they have a lasting impact.

Effective supply management

Supplier networks may expose brands, retailers, and manufacturers to non-compliance issues if they are not adequately controlled. Eliminating time-consuming and costly compliance mistakes while also strengthening working relationships with third parties is only possible through improving communication with those parties.

Streamlining compliance checks

A company's ability to introduce items into the market rapidly depends on being able to swiftly detect any product flaws and acquire insight into which suppliers perform the best. Product recalls can be minimized, consumer confidence in brands and merchants can be built, and your company's image can be preserved if noncompliance is quickly identified.

Webinar Replay: How the GoSaaS Environmental Governance & Compliance Solution (EG&C) Compliments Your Oracle PLM System

If you are familiar with Oracle’s Agile PG&C solution, using a different compliance tool, or really just don’t know where to start - you won’t want to miss this informative event!

Compliance begins with a foundation of knowledge and continues throughout the product's lifecycle. Regulatory design faults can result from a failure to focus on regulatory requirements. When regulatory design faults are found early in the product development process, they are usually simple to fix. However, the later an issue is discovered, the more expensive it will be to resolve. When design problems emerge at inconvenient periods, such as after a product has been sold and delivered, they can quickly grow into "Moments of Regulatory Crisis." Moments of Regulatory Crisis are periods of time when previous inattention to compliance issues turns into serious, and sometimes public, issues. Therefore, product designers must, without a doubt, adhere to regulatory requirements. PLM compliance will likely become normal practice in the near future as the strategic and product quality benefits of design for compliance are well understood.

With PLM, companies have comprehensive data traceability from the beginning of design until product release. Furthermore, industry-specific solutions streamline the whole compliance process by ensuring that organizations can fulfill relevant laws right from the start.

Do you need an implementation of a quality compliance solution? Get in touch with GoSaaS today.

Share this

- Oracle Cloud PLM (10)

- "Oracle" (7)

- Oracle PLM Cloud (6)

- logistics (6)

- Cloud Migration (5)

- Cloud PLM (5)

- ERP System (5)

- GoSaaS EG&C (5)

- OTM (5)

- SCM (5)

- "Agile" (4)

- Agile Product Lifecycle Management (4)

- GoSaaS ETS (4)

- WMS Cloud (4)

- supply chain management (4)

- GoSaaS, Inc. (3)

- Integrations (3)

- On-Premise to Cloud (3)

- Oracle E-Business Suite (3)

- Oracle PD (3)

- PLM Cloud (3)

- connected digital supply chain (3)

- "GoSaaS" (2)

- Digital Transformation (2)

- GoSaaS Employee Training System (2)

- GoSaaS Healthcheck (2)

- GoSaaS Integrator (2)

- GoSaaS Migrator (2)

- HR (2)

- High-Tech Industry (2)

- Industry 4.0 (2)

- Manufacturing Industry (2)

- Oracle Agile PLM, (2)

- Oracle EBS (2)

- Oracle HCM Cloud (2)

- Oracle PDH (2)

- Oracle Product Lifecycle Management (2)

- Oracle Product Lifecycle Management Cloud (2)

- Oracle Quality Management (2)

- PLM upgrade (2)

- Semiconductor (2)

- "EG&C" (1)

- "PLM" (1)

- AI (1)

- Analytics (FDI&AI) (1)

- Arena PLM (1)

- Cloud Implementation (1)

- Cloudworld Austin (1)

- ERP Analytics (1)

- GoCompliance (1)

- GoSaaS CRM (1)

- GoSaaS Digital Thread, (1)

- GoSaaS Migration (1)

- GoSaaS PLM (1)

- GoSaaS System Healthcheck (1)

- GoSaaS implementations (1)

- IIoT (1)

- LasVegas (1)

- Life Sciences (1)

- Load Test (1)

- MBX2019 (1)

- Medical Device Industry (1)

- On-Premise (1)

- On-Premise Agile PLM (1)

- Oracle Agile Product Lifecycle Management (1)

- Oracle Business Applications (1)

- Oracle Enterprise Data Quality (1)

- Oracle Fusion Cloud (1)

- Oracle PLM (1)

- Oracle Product Data Hub Cloud (1)

- Oracle Redwood (1)

- Product Value Chain (1)

- Propel PLM (1)

- Security Check (1)

- Smart Technology (1)

- System Healthcheck (1)

- System Review (1)

- Upgrade to Cloud PLM (1)

- Yearly Review (1)

- regulatory compliance (1)

- July 2025 (1)

- June 2025 (1)

- May 2025 (1)

- April 2025 (1)

- March 2025 (4)

- February 2025 (3)

- January 2025 (3)

- December 2024 (5)

- July 2022 (1)

- May 2022 (3)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (2)

- November 2021 (1)

- September 2021 (2)

- July 2021 (1)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- January 2021 (2)

- December 2020 (1)

- October 2020 (1)

- September 2020 (1)

- August 2020 (1)

- June 2020 (1)

- May 2020 (1)

- September 2019 (1)

- June 2019 (1)

- April 2019 (1)

- March 2019 (2)

- June 2018 (1)